Flex Films launches high barrier metallized polyester film- FLEXMETPROTECT F-HMB

Flex Films, the global motion picture manufacturing arm of India's largest flexible packaging manufacturer, Uflex has developed a high barrier metallized polyester film – FLEXMETPROTECT F-HMB picture. Metallized polyester films are popular for providing loftier barrier properties to laminated flexible packaging structures.

However, it is observed that poor adhesion of metal with the base polyester film may result in laminate failure, thereby having an agin impact on the functioning. Currently, the films with high metallic adhesion for superior bulwark properties for harsh environments in the marketplace are limited and costly.

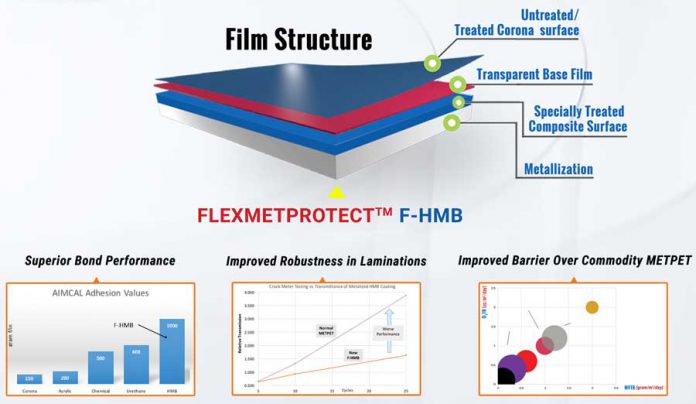

Flex Films's new product is either untreated or corona treated on the other surface, while metallization is carried out on the specially treated composite surface imparting metal adhesion or bail strength of greater than 1200 gram-strength per inch. Various film manufacturing plants of the company located at various parts of the world will supply the newly released production.

Talking about the new development, Steven J. Sargeant, general manager, Engineering science at Flex Films, says, "The adhesion of the metal on BOPET base film is the sum of chemical and mechanical adhesion. Our proprietary surface treatment on the base motion-picture show allows increased levels of chelation or reaction with the metal being deposited, thereby resulting in a better adhesion profile. The specialized surface handling has materials with unique and enhanced properties, thereby resulting in enhanced mechanical bonding. It took us almost 18 months to engineer this motion-picture show."

The new product volition benefit converters, and elaborating upon its utilise, Vijay Yadav, business organisation head, Flex Films, says, "The pic offers class leading high adhesion to metal under almost ambitious environmental conditions; demonstrates improved scuff, scratch and craze resistance, thereby improving yields upwards to four percent and offering unparalleled robustness in processing and performance for converters; has OTR of 0.6 cc/m2/solar day at 23 degrees centigrade and 0% RH and MVTR of 0.6 g/m2/day at 38 degrees centigrade and 90% RH offering high bulwark properties thereby bringing new concepts to the market place; complies with EU and FDA regulations for food class applications and happens to exist cost effective. The picture has extensive utilise in liquid packaging, stand up pouch applications, barrier layer in challenging applications like 'bag in box', chemical packaging, pharma packaging, hot make full applications up to 80-degrees centigrade and others. This film is available in 8 – 50 micron thickness range."

Sharing his views virtually the potential of the new product, Anantshree Chaturvedi, vice chairman and chief executive officer of Flex Films says, "Flex Films is focusing on speciality substrates that add value to the business of converters and their customers by enhancing the quality and profile of the resultant packaging. Our expansion strategy hereafter volition be production driven and not commodity driven. The product is a technologically superior film with encouraging demand. In the US, the market for this specialized film is expected to exist about 25% of the current metallized flick market."

Lastly, congratulating the engineers, Ashok Chaturvedi, chairman and managing director, Uflex Limited said, "FLEXMETPROTECT F-HMB is a archetype instance of value engineering that shall bring substantial benefits to the converters globally. This is innovation to create value added differentiation."

Source: https://packagingsouthasia.com/packaging-production/flex-films-launches-high-barrier-metallized-polyester-film-flexmetprotect-f-hmb/

0 Response to "Flex Films launches high barrier metallized polyester film- FLEXMETPROTECT F-HMB"

Post a Comment